The addressable led strip lights(sometimes it is called programmable led strip lights, SPI digital led strip lights, or led pixel strip) means that they can have multiple colors on the same strip. Unlike other led strip lights, the entire strip must be the same color.

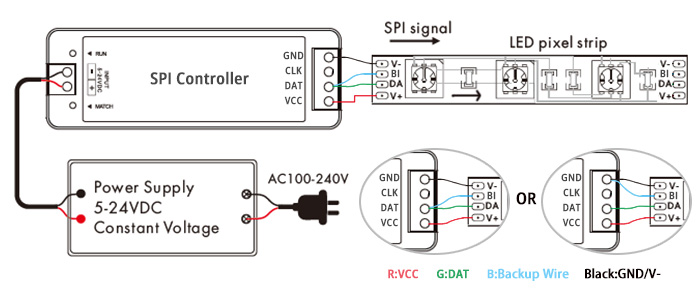

About addressable led strip lights, the positive and negative poles are power lines, and the others are signal lines.

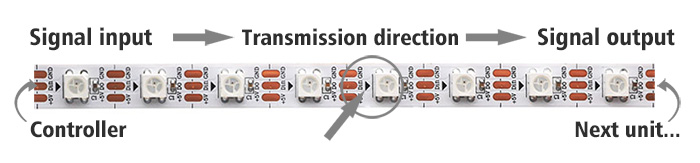

For signal transmission, the signal line should not be missed. The arrows of the led strip indicate the direction of data flow. If the SPI controller is not installed on the data input side, it will not work.

If the addressable led strip needs to be powered separately, the power line should be connected to the power supply.

Don’t worry about how to judge whether the addressable led light strip needs a separate power supply, it will be discussed in detail in the following content.

| Addressable LED | V+(Red) | V-(Black) | Signal 1(Green) | Signal 2(Blue) | Address |

| Single Signal | VCC | GND | DAT | ||

| Dual Signal | VCC | GND | DAT | CLK | |

| Breakpoint Resume | VCC | GND | DAT | Backup | |

| DMX LED | VCC | GND | A/DMX+ | B/DMX- | PI |

Part 1. What controller to use for your addressable led strips?

Part 2. How to install addressable led strip lights?

Part 3. How to judge if the addressable led strip lights need to be powered separately?

Part 4. How to wire long addressable lighting strips?

Part 5. How to solve the LED light flickers?

What controller to use for your addressable led strips?

The addressable led strip can be connected to a compatible controller to send commands to the addressable LED.

►SPI controller

The SPI controller supports WiFi, RF, Bluetooth, Music, and Voice control(Alexa and Google Assistant).

Built-in hundreds of well-written programs, users can choose the type through their hobbies, and use them for home and simple lighting projects that don’t know how to program.

Advantages: Many procedures, low difficulty.

Disadvantages: Unable to choose a special program.

Please pay attention to two points about the SPI controller:

1) Whether the SPI controller can control the IC type of your addressable led strip.

2) The pixel of the SPI controller must be larger than the pixel of the addressable led strip to ensure that the LED lights of the entire light strip are controlled. We have mentioned above how to calculate the pixel.

| Total pixels of addressable led strip = Pixels(ICs)/meter*Length |

How to solve the problem of insufficient pixels of the SPI controller?

1) Change to an SPI controller with more pixels.

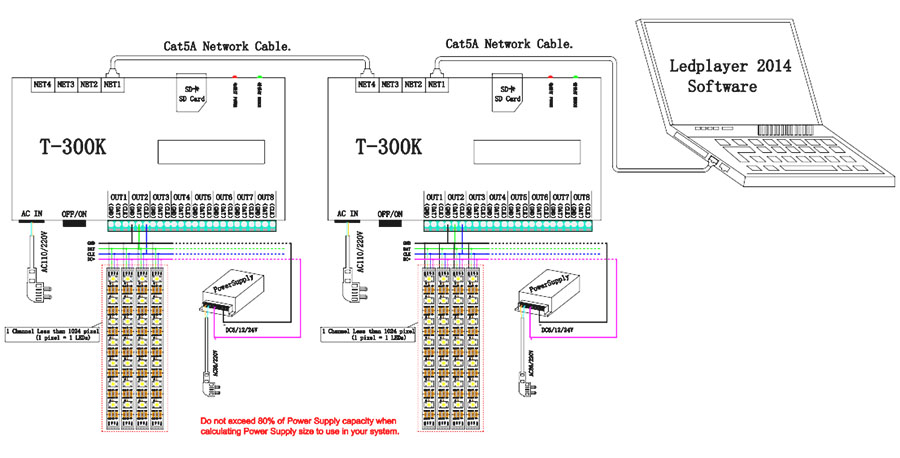

We have the SPI controller that can connect 4 addressable led strips or 8 led light strips in parallel, which combines the functions of the SPI controller and the SPI amplifier.

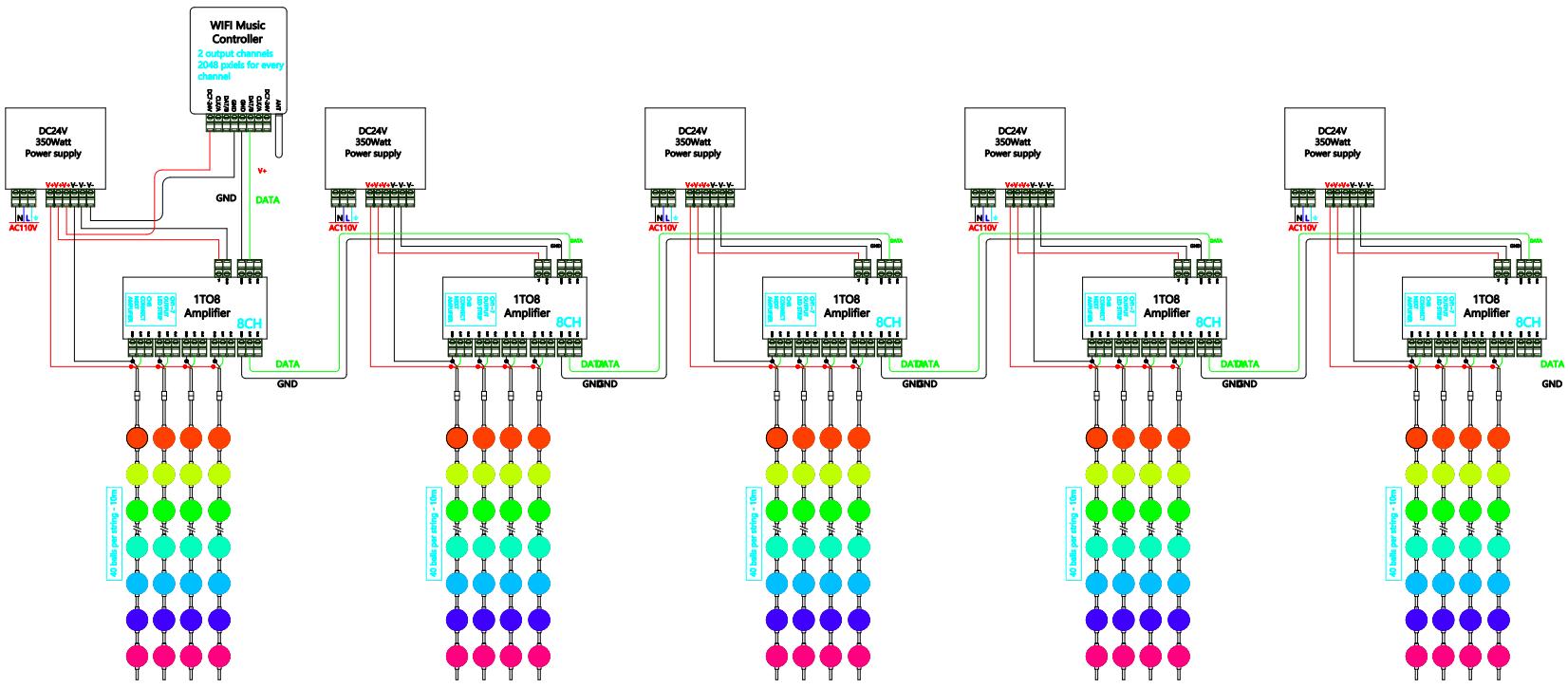

2) Add one or multiple addressable SPI multi-channel amplifiers to amplify the pixels.

The SPI amplifier has a completely different function from the non-addressable led strip lights amplifier. The number of pixels of the SPI amplifier is amplified by multiple channels.

For example, the SPI controller has 600 pixels built-in, and 8*600 pixels can be connected behind the 8-channel amplifier.

3) Use WIFI or RF function to wirelessly synchronize multiple SPI controllers.

The grouping function should be controlled by a mobile phone, and there are single-channel controllers and dual-channel controllers.

►Programmable controller

The programmable controller is more flexible than the SPI controller and can write any programs and dynamic effects you want.

But the disadvantage is that the requirements are high. You need to understand AutoCAD or FLASH software and be able to operate LED Edit 2020 programming software.

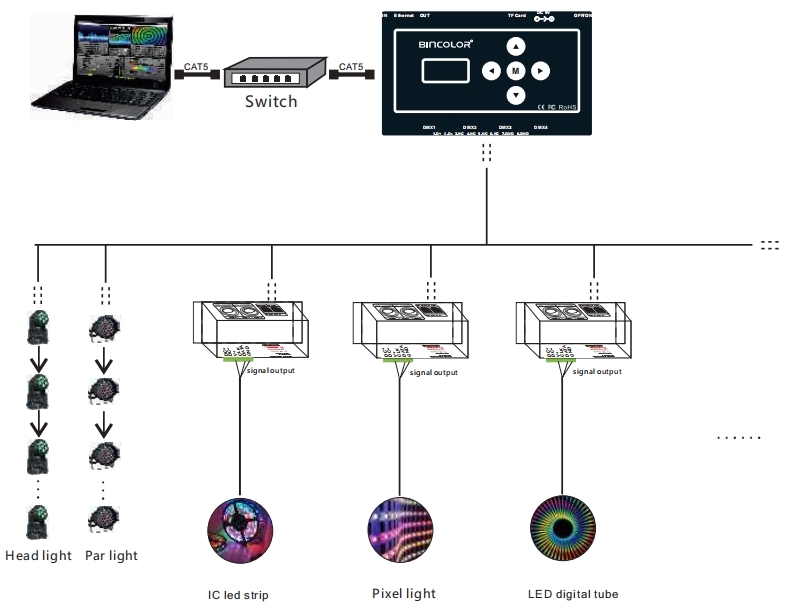

►Art-net DMX controller

The Art-net DMX controller can control multiple groups of SPI light strips step by step or individually, or combine other DMX items to control.

Disadvantages: Need to be able to use Mardix software.

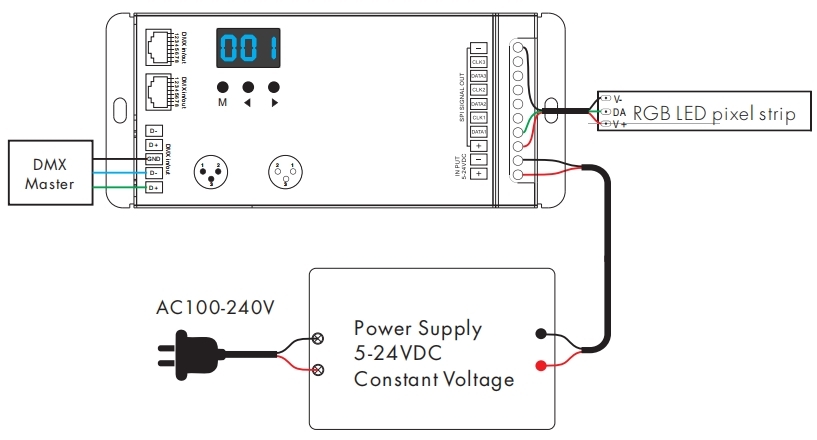

►DMX to SPI decoder

DMX to SPI decoder converts DMX signal into SPI signal, which is used for DMX console to directly control SPI light.

►Open-source development board

The open-source development board is represented by Arduino UNO and Raspberry Pi. The development board is small and easy to use. It can be used in complex environments and DIY projects, but it needs to know how to program.

How to install addressable led strip lights?

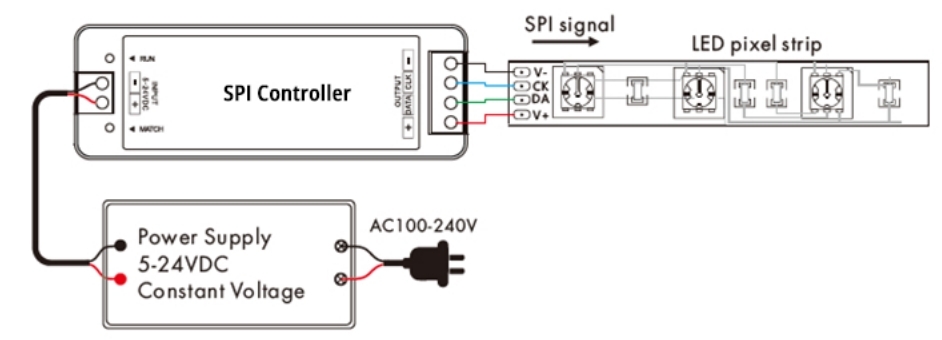

►Connection method one:

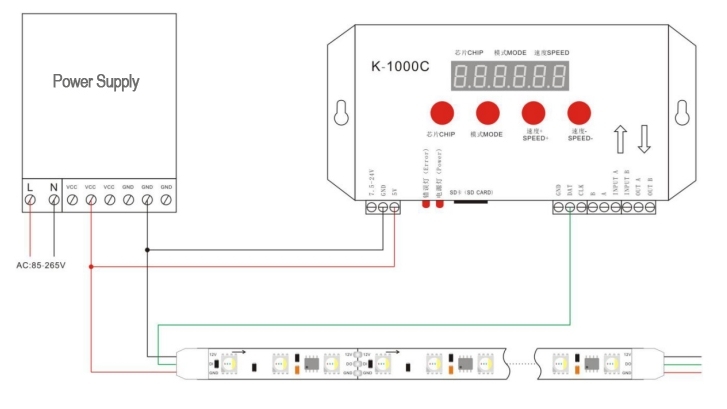

When installing the addressing led strip light, the SPI controller is best installed next to the power supply.

SPI controller is too far away from the power source, which will affect the stability of the control signal to a certain extent.

If the power supply, the SPI controller, and the addressable led strip are not in the same place, we usually choose to extend the distance between the light strip and the SPI controller, but this has the disadvantage that the SPI signal will attenuate.

This signal attenuation can cause LED lights to flicker when running long addressable led light strips. The problem of SPI signal attenuation can be perfectly solved by installing a mini amplifier at a point in front of the light strip. We will mention in detail the light strip flickers later.

This connection method is suitable for low-power addressable led strip lights installation, and the length is best no more than 5 meters.

Connecting the addressable led strip to the SPI control is really a simple thing, even if you are a novice, you can do well. You just only connect the corresponding signs correctly. The addressable led strip is driven by energy through the SPI controller.

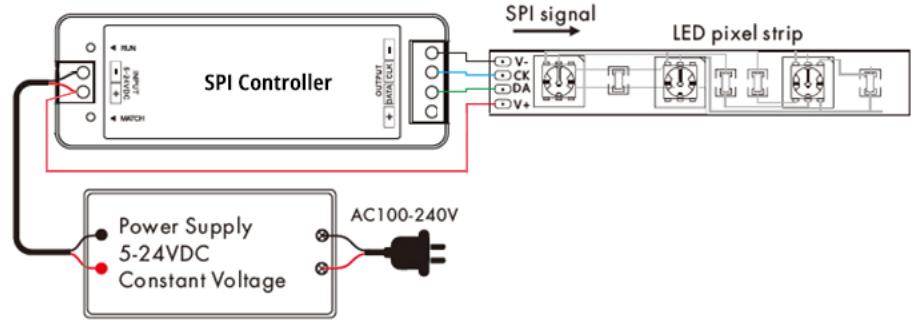

►Connection method two:

If the power of the addressable led strip is too high, we are recommended that the SPI controller and led strip be powered separately. It makes the control signal more stable.

In the first connection method, if the power of the light strip is too high, the SPI controller is overloaded which means the power of the controller is less than the power required by the addressable led strip, lighting the led strip will burn out the SPI controller.

Sometimes, there will be a mismatch between the control result and the control command, or it will be directly disordered.

If you find this situation, maybe your controller is good at all, but the power of the programmable led strip is too high and it needs to be powered separately.

Please pay great attention to the meaning of the separate power supply for addressable led strip lights. The light strip is supplied with energy through the power source, not through the controller.

On some programmable led light strips, you will see a 3-pin and a 2-pin connector. The 3-pin connector is used to transmit signals, and the 2-pin connector is used to connect to the power supply.

However, please note that when the 2-pin connector is connected to the power supply, the SPI controller is only used to transmit signals, the VCC of the 3-pin connector must be cut off.

►How to connect the 3-pin JST connector to the Breakpoint Resume LED strips?

Sometimes, the dual-signal SPI controller can also use other light strips such as breakpoint resume LED strips.

The most important thing is that there is a negative pole, a positive pole, and a signal line. The backup wire of the breakpoint resume led strip can be connected to the negative or the signal wire of the SPI controller.

By analogy, a single-signal SPI controller can also be used for the breakpoint resumable led strip, because its two signal lines(BI and DA) can share a connection point (DAT).

| SPI Controller | Addressable LED Strip |

| Single-signal SPI controller(GND, DAT, VCC) | Single-signal LED strip |

| Breakpoint resume LED strip(DA and BI share DAT) | |

| Dual-signal SPI controller(GND, CLK, DAT, VCC) | Single-signal LED strip(CLK not used) |

| Dual-signal LED strip | |

| Breakpoint resume LED strip(DA and BI share DAT, CLK not used) |

How to judge if the addressable led strip lights need to be powered separately?

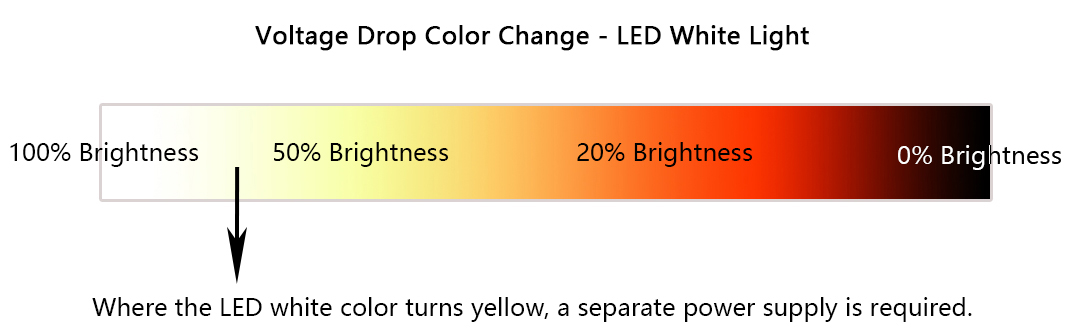

When there is a voltage drop, it means that the power is insufficient and requires a separate power supply.

►What is voltage drop? How to solve the voltage drop?

The most obvious way to judge the voltage drop is when the LED brightness is working at 100%, the brightness is attenuated, and it needs to be powered separately at the nearest attenuation point.

The dynamic effect may not be able to distinguish whether there is a voltage drop.

Turn on the addressable led strip light with white light and adjust the brightness to the brightest. At this time, the voltage drop of the led strip can be clearly observed.

►LED Density and Voltage Drop

However, you need to pay attention to the density of the addressable led strip will affect the length of the voltage drop. The denser the density, the greater the voltage drop, and the shorter the distance between points that require a separate power supply.

| 30-60 LED/m Addressable LED Strip | Voltage Drop | Solution |

| DC5V | Have voltage drop(5m) | Supply power separately at both ends(5m) |

| DC12V | Without voltage drop(5m) | Power supply at one end(5m) |

| DC24V | Without voltage drop(10m) | Power supply at one end(10m) |

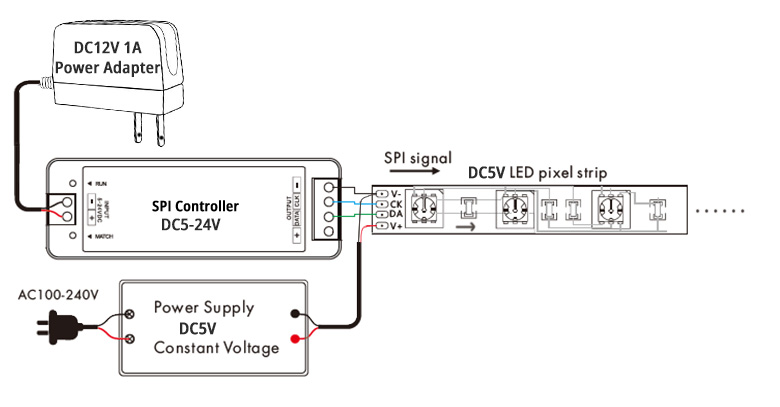

►How to power addressable LED strip and SPI controller using different voltage power supplies?

There is another case of a separate power supply. The low-voltage addressable led strip runs too long and the current is too high, causing the SPI controller signal output to be unstable.

In this case, adding a 12V 1A or 24V 1A power adapter to the SPI controller can solve this problem well, ensuring that the SPI controller is only output signal(The VCC/V+ of the light strip is not connected to the output positive pole of the SPI controller).

And do not forget to supply power to the light strip normally(Follow the 80% rule).

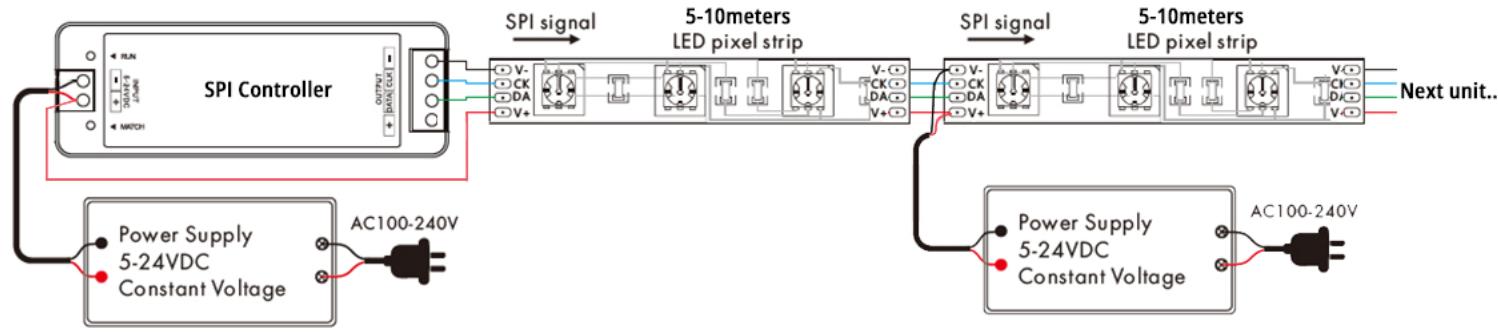

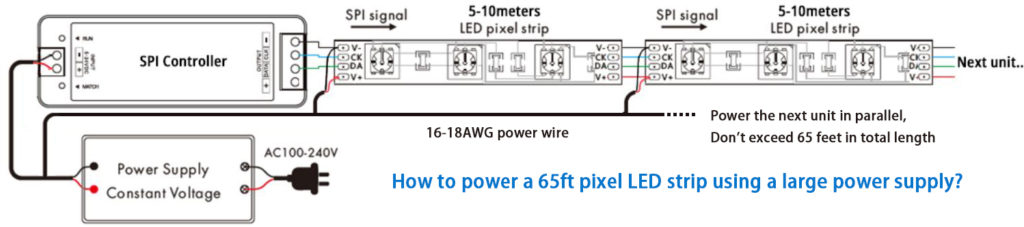

How to wire long addressable lighting strips?

There are two common long-distance wirings. One is to directly use an ultra-long-distance addressable led light strip.

For running long distances, there are some addressable led strip light kits for you, up to 20 meters long RGB neon light kit and up to 50 meters long addressable light strip kit.

We provide the controller and power supply options in the kits, solving the trouble of choosing the right controller and power supply.

If the project is a circle, the two ends of the light strip can be touched or overlapped, and the same power supply can be shared.

And if the project is linear, two power supplies are required to supply power to both ends of the light strip separately.

The second to achieve long led light strips installation is to connect multiple addressable led strip lights.

Both the SPI controller and the light strips need to be powered separately. Where there is a voltage drop, a separate power supply is required.

How to solve the LED light flickers?

This kind of problem is usually caused by the following two factors.

►1. The addressable light strip is too long or the SPI controller is too far away from the light strip, causing the SPI signal to attenuate.

We need to add a MINI SPI amplifier in the closest area of the flicker.

This amplifier is different from the above multi-channel amplifiers in that it only amplifies the attenuated SPI signal and cannot be amplified multiple times.

Watch the video to find out how to solve the flicker caused by the signal delay of the addressable LED strip.

►2. Different countries and regions lead to insufficient output power or low frequency of wide-voltage power supplies.

In North America, choose single-voltage power supply AC110-130V input as much as possible, and multiply the power of the light strip by 1.5 times when calculating the power supply in order to ensure sufficient output power of the power supply.

If your led strip light requires 100W, then you’d better choose a 150W power supply. We have added a link for you on how to calculate the power for your led strip lights. You can click to jump to the page.

The output power in the European AC220-240V region will be more sufficient and there will be fewer problems.

The following table is for reference only.

| Power | Input | Output |

| 100W | AC110-130V | 90W |

| 100W | AC 85-265V | (AC110V)60W (AC220V)100W |

| 100W | AC220-240V | 100W-110W |

More LED strip wiring diagram: