Space is the essence of architecture, and light is the soul of space. The appearance of led strip lights increases the layering of the indoor and outdoor environment, making the space environment softer and more emotional. In the minimal space form, the light strips can also give it a breathtaking level of beauty.

COB led lights are different from ordinary led strip lights. I hope you can understand a little more about COB led strips after reading this article. No matter if you know COB before or not, this article will bring you gains, don’t miss it.

Part 2. How is COB led strip made?

Part 3. Different types of COB strip lights

Part 4. Are COB led lights better?

Part 5. How to cut and connect COB led strips?

Part 6. How to install COB led light strips?

Part 7. Further reading: SMD VS COB, COB VS LED, Why choose superlightingled.com?

What is COB LED?

COB is the abbreviation of Chip on Board, which means chip-on-board packaging technology, a light-emitting body in which multiple COB LED chips are integrated and packaged on the same substrate.

COB led light source is a high-efficiency integrated surface light source technology in which the LED chip is directly attached to a high-reflectivity mirror metal substrate.

The light-emitting area and external dimensions of the light source can be designed according to the product shape and structure such as round or square.

The led light emitted by the chip undergoes refraction, reflection, and interaction with phosphors in the encapsulating gel, and the gel uniformly emits light of different light colors and color temperatures.

How is COB led strip made?

After making the COB substrate, apply a white coating. Use the SMT machine to attach the COB chip to the flexible PCB board.

Cover the silicon wafer placement point with a thermally conductive epoxy on the surface of the substrate, then place the silicon wafer directly on the surface of the substrate, heat treatment until the silicon wafer is firmly fixed on the substrate, and then use wire welding to connect the silicon wafer and the substrate and establish an electrical connection directly between them.

Finally, encapsulate the COB light strip. After the production is completed, cut into a strip of light and roll it into a reel.

And this is how the COB led light we have seen was produced.

This technology eliminates the concept of stents, so the process is reduced by nearly one-third, and the cost is also saved by one-third.

Different types of COB strip lights

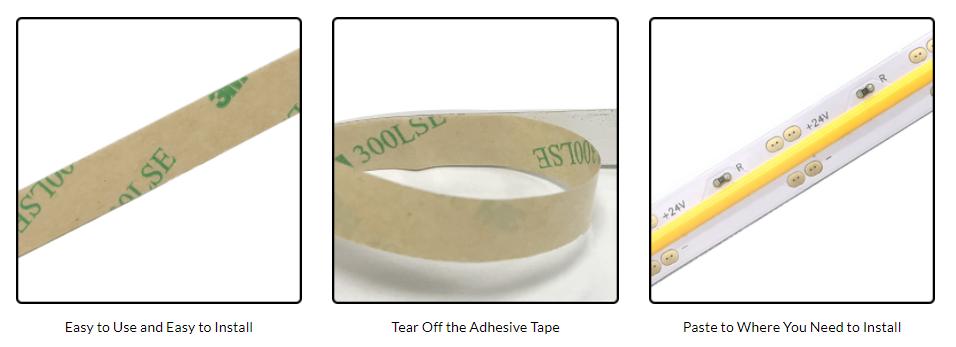

COB led lights have the basic characteristics of led strip lights, have an adhesive backing, can be cut, can be connected, long life, safe to touch, environment friendly, and is easy to install.

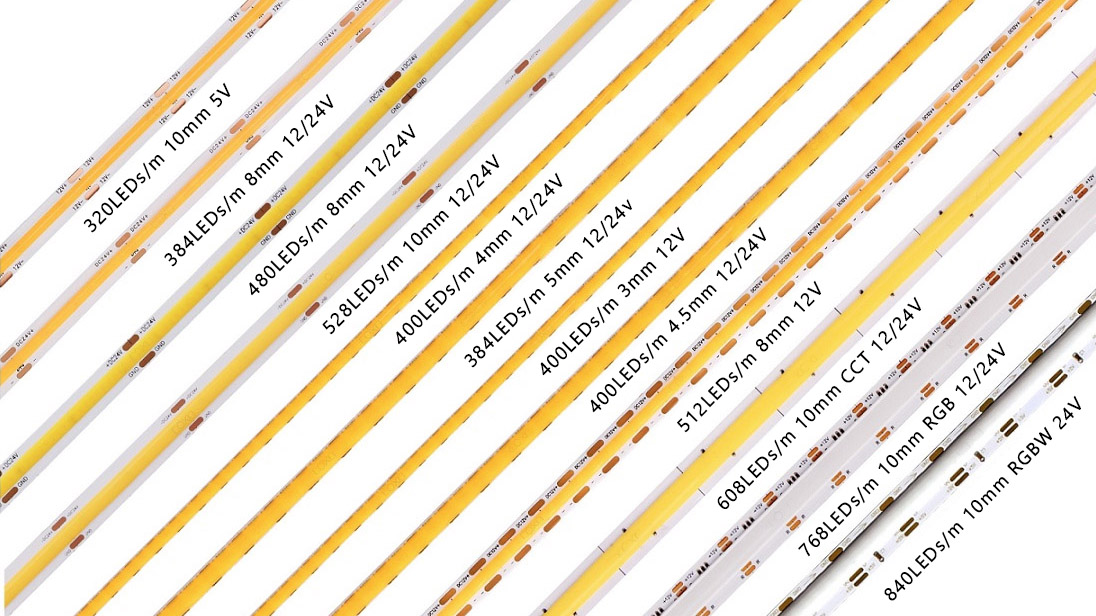

There are many types of COB led strips, different voltages, different widths, different densities, different light colors and color temperatures, and COB LEDs all have high CRI.

| • Voltage: 5V / 12V / 24V • Density(chips/m): 160, 320, 400, 384, 480, 512, 576, 840, 768, 864, 1056 • Flexible PCB width: 3mm | 4mm | 5mm | 8mm | 10mm | 12mm • White light color temperature: 2200K / 2700K / 3000K / 4000K / 6500K • Color: Amber, White, Ice blue, Pink, Yellow, Orange, Red, Green, Marrs green, Blue, CCT, RGB, RGBW, Addressable RGB • CRI(Ra>): 90+ |

Are COB led lights better?

Comparing COB led strips and other led strip lights, we can see that COB light strips are indeed slightly better. And the advantages are expressed in the following aspects.

►Bending resistance, good flexibility, 180-degree light-emitting

Led strip lights are limited in flexibility, which only can be bent to align the lights horizontally and bend to the back of the strip.

But, COB led strip lights are available to be wound, twist, and bend. The COB strip is more flexible than led strip lights.

The light-emitting surface of the COB strip light can reach a light-emitting angle of 180°. However, SMD led strip lights only can reach 120 degrees.

►Energy-saving, high light efficiency

Compared with traditional led strip lights, under the same density, the power of COB led lights is much smaller and only accounts for about 50% of the traditional led strips.

And COB led light can achieve high luminous efficiency while saving energy.

►Low heat, good heat dissipation

The COB light strip directly fixes the chip on the PCB, reducing the heat conduction channel, and the high-density technology makes the current on each chip doubled, the heat dissipation performance is qualitatively improved, and the light attenuation of the COB light strip is smaller and longer life.

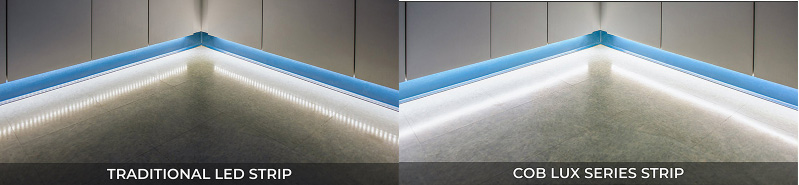

►Uniform light effect, soft, no glare, no light spots, no graininess

Due to the structural characteristics of the COB led light, the light-emitting surface is a linear colloid. The structure of the SMD light strip is a luminous lamp bead.

Therefore, the light emitted by the COB light strip should be much more uniform, linear, and there is no light spot.

►Multicolor, dimmable

Led strip lights have various colors and color temperatures, and the COB led strips are as the same. You can choose your preferred color and color temperature, 3000K warm white or 6000K pure white? Single color or RGB color changing COB led strip?

The brightness of led strip lights doesn’t always make us pleasant. If the strip light can be adjusted the brightness, it will be great to set up the comfortable brightness.

Actually, you can choose a wall control panel or handheld remote control to adjust the brightness of COB led strip lights with a dimmer, from 0 to 100, from the darkest to the brightest.

When choosing led light controller and led power supply for your project, please look for a suitable product. Carefully confirm whether important factors such as voltage and power are correct, and avoid buying inappropriate products.

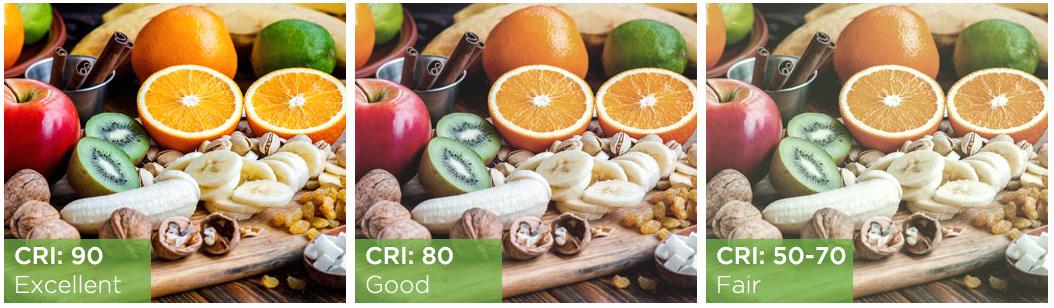

►Ultra-thin, high density, high CRI

Since the COB led chip is directly attached to the PCB board, the thickness of the PCB is ultra-thin. If you want to hide the led strip, ultra-thin strip lighting is a good choice.

The high-density COB led light strip achieves perfect linearity from point to line to surface, which is more in line with the current designer’s design concept of not seeing the light, and the application field will be broader.

High CRI means that the light source can restore more colors to the objects. COB led strip lights with high CRI make your senses more intense and easier to distinguish different colors.

A good led strip light cannot do without good color rendering. You can imagine you are in a garden, and there are many beautiful flowers. With high CRI, you can see the beauty of the garden, and you will feel a variety of bright colors.

But with low CRI, everything you see will be grayscale, like the black and white movie. And all it says is that a high CRI is necessary.

How to cut and connect COB led strips?

A variety of led strip lights have the ability to be cut in order to better adapt to different installation needs. And COB led light is no exception.

Find the cutting line of COB led strip lights and cut along it. Do not cut to other areas. All the led strip lights only sign with cut lines can be cut. Other areas once are cut, will cause damage to the light strip. So be careful.

You can choose led light connectors to connect COB led strip lights or connect the light strips by soldering. These two ways are available to use. You can select the way you like.

How to install COB led strip lights?

1. The required length of the COB light strip should be measured in advance.

2. COB light strip with interface plug cannot be reversed.

The light strip is an LED diode and is driven by DC, so there are positive and negative poles. If the positive and negative poles are connected reversely, the light strip will not light up. If the connecting plug does not light up when the power is on, you only need to disconnect the other end of the light strip.

3. Place the COB light strips correctly.

Most of the light strips are in the original packaging of the coiled wire. The newly opened light strips will be distorted and difficult to install. You can arrange them first, and then install them. Since the COB light strip emits light on one side, if it is placed unevenly, uneven brightness and darkness will appear, especially at the corners.

4. Pay attention to the installation environment.

The dust around the COB led light must be cleaned up because the dust can easily cause open flame accidents when heated.

| Single color COB | How to wire single color led strip lights? |

| CCT tunable white COB | How to wire tunable white/CCT led strip lights? |

| RGB COB | How to wire RGB color changing led strip lights? |

| RGBW COB | How to wire RGBW led strips? |

| RGB+CCT COB | How to wire RGBCCT led strip lights? |

| Addressable COB | How to wire addressable led strips? |

Can COB led lights use aluminum channels?

The role of the led aluminum channels is to protect led strip lights and to emit a better light effect. If you don’t want to see the led strip light naked, you can install an aluminum channel to hide the light strip. The use of aluminum channels can also make the installation effect more beautiful.

The use of light troughs for COB led lights can solve the visual flaws of reflective particles. Whether it is an office, a commercial shop, or a leisure space, the linear light style can bring visual extra points to the space when providing lighting.

Recommended reading: Ultimate Guide on Aluminum Profile for LED Strip Lighting

Further reading

What is the difference between SMD and COB led?

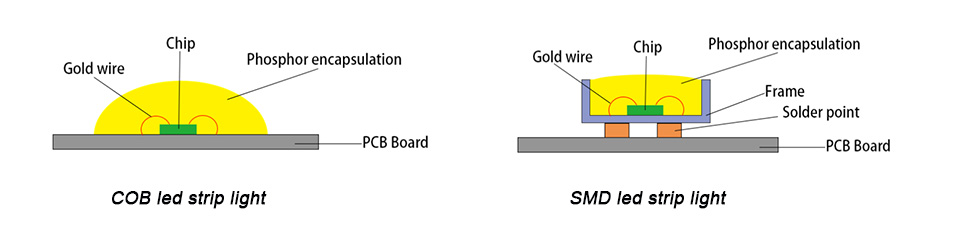

From the picture below we can clearly see the difference between COB and SMD.

The COB led light chip is directly attached to the PCB substrate.

SMD refers to surface mount technology. The LED lamp beads are fixed on the bracket of the PCB board and do not directly contact the PCB board.

Their structures determine that their light-emitting angle, PCB board flexibility, LED light density, light-emitting effect, heat dissipation, CRI, and other aspects have a difference.

What is the difference between COB and LED? COB VS LED

COB led light has high color rendering property, and the light color is close to natural color. No flicker, no glare, no electromagnetic radiation, no ultraviolet radiation, no infrared radiation, and can protect eyes and skin.

LED strip uses light-emitting diodes as the light source to directly convert electricity into light.

LED is the third generation of lighting technology after incandescent lamps and fluorescent lamps. It has the characteristics of energy-saving, environmental protection, safety and reliability, no flicker, and no ultraviolet radiation. The disadvantage is the blue light hazard.

Why choose superlightingled?

• In-depth cooperation with the production factory, with a technical guarantee

• Can customize led strip light for you according to your actual needs, such as different color and color temperature, suitable length, waterproof level, etc, and keep the product batch consistent.

• In stock, can be shipped on the same day

• Fast shipping, choose DHL

If you need help or have doubts about the led strip light, contact us.