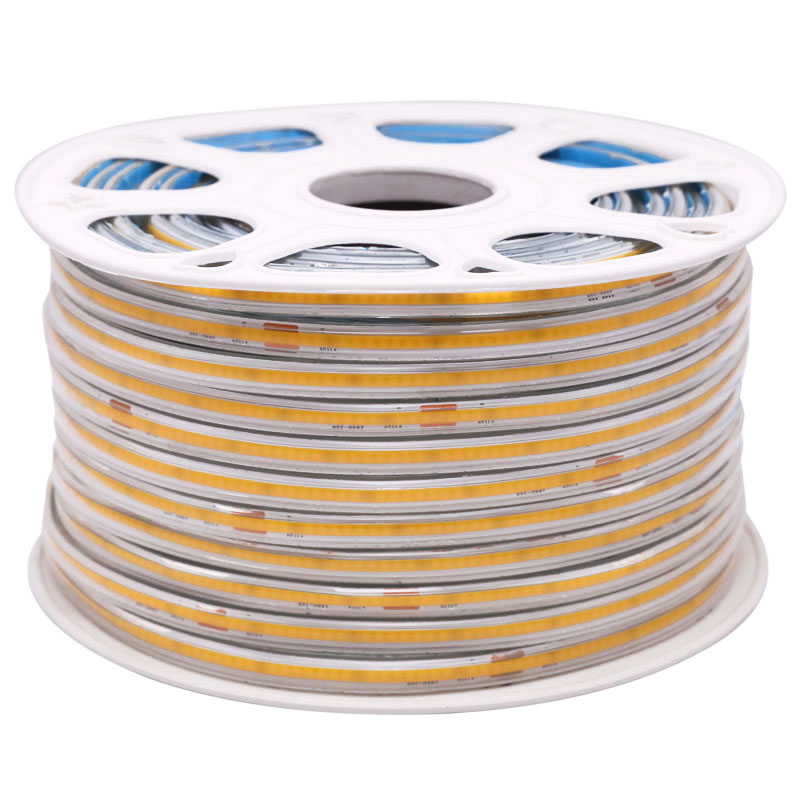

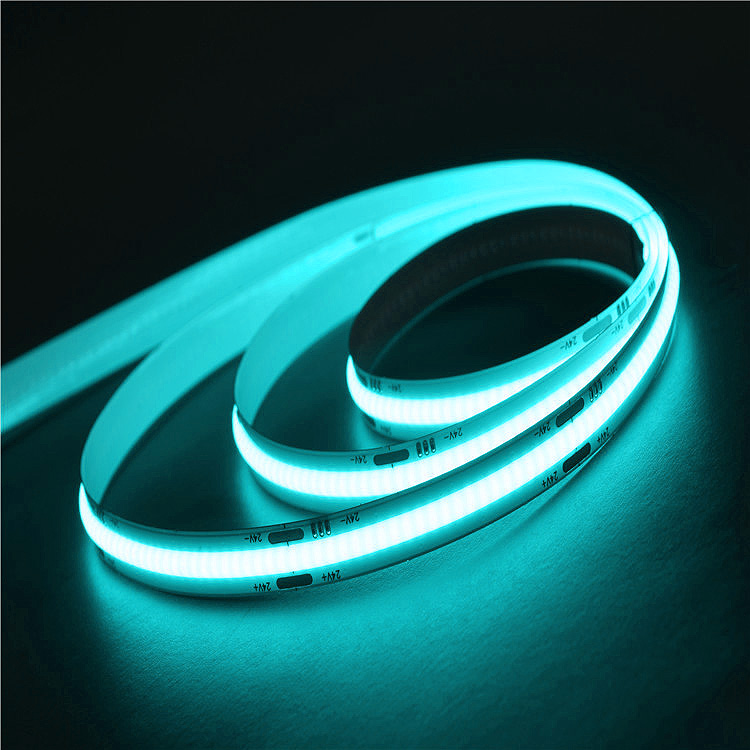

Flexible COB LED Strip Lights

As a professional China COB led strip light manufacturer and online seller, SuperLightingLED specializes in providing high-quality and innovative lighting strip solutions in the COB led market. Focusing on product diversification, we offer a wide range of specifications and types of COB led strips to meet the individual needs of different customers in multiple scenarios, such as commercial lighting, home decoration and outdoor landscape. With our professional R&D team, we are always at the forefront of the COB chip-on-board led technology strip industry, providing retail customers and wholesalers with efficient, energy-saving and reliable COB lights products.

What is a COB LED Light?

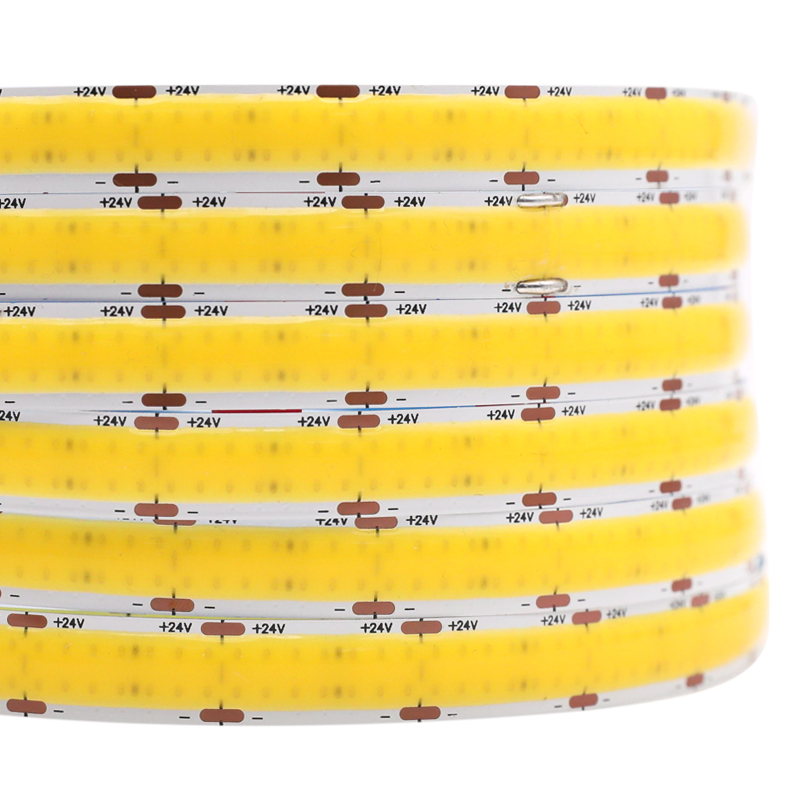

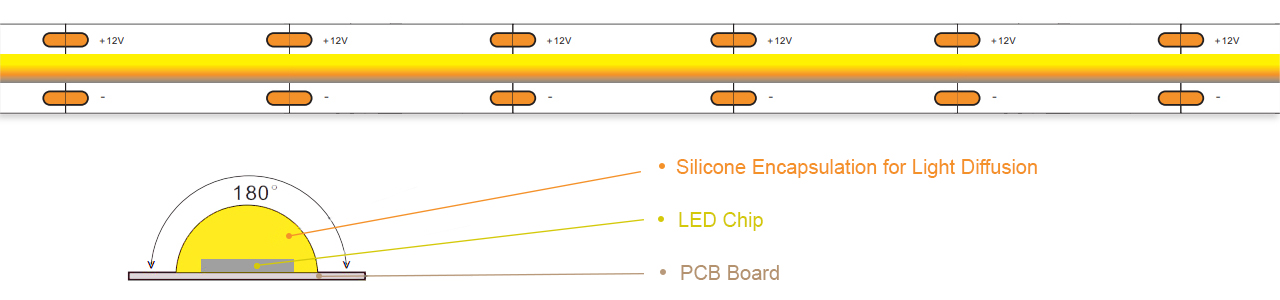

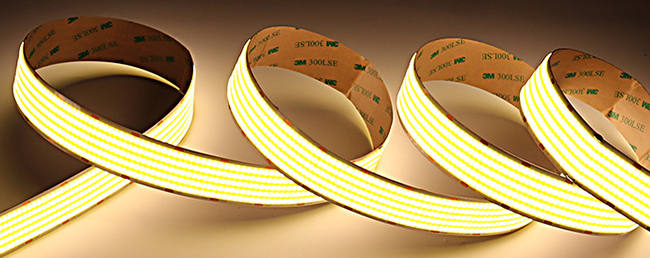

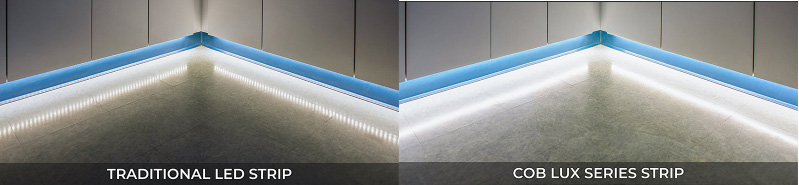

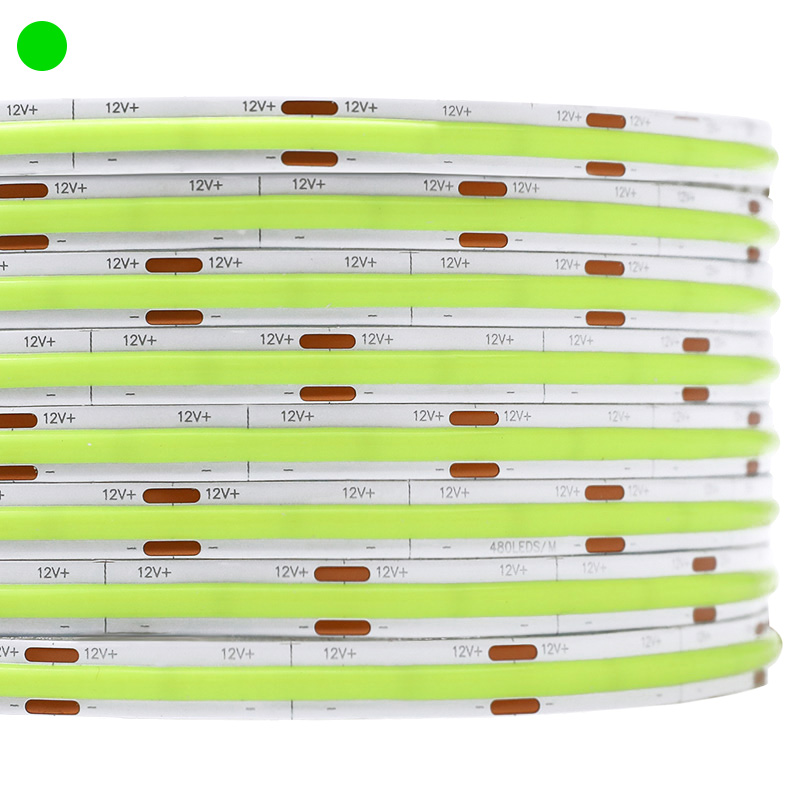

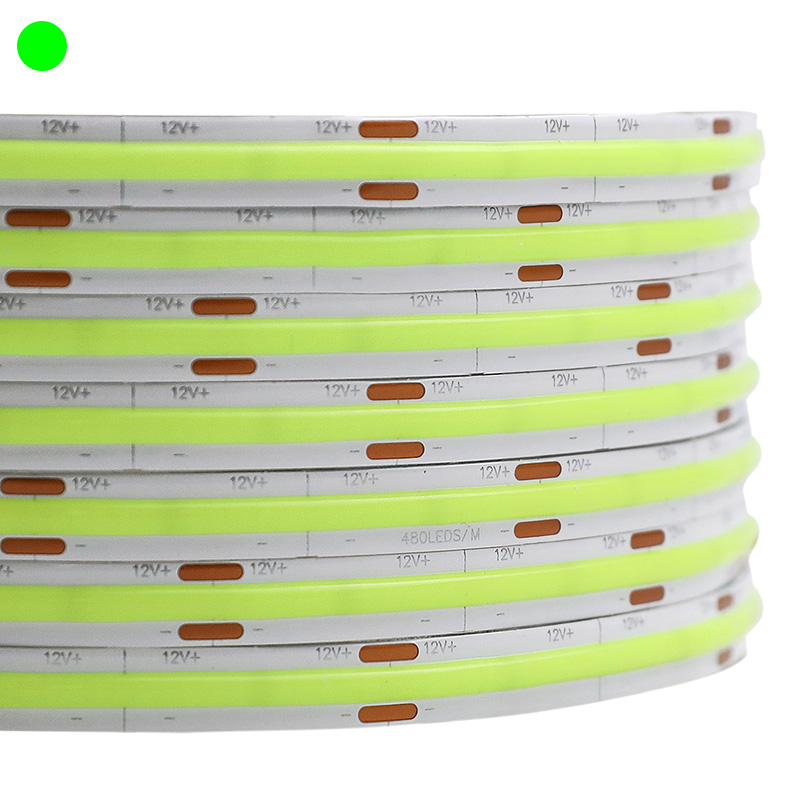

COB refers to chip on board technology, which means the c o b LED chips are mounted directly on the FPCB (flexible printed circuit board), also known as FCOB LED, and the light of COB chips is diffused by a linear silicone encapsulation. So chip on board led strip can strengthen heat dissipation and improve LED glare effect with the characteristics of high density and soft uniform light.

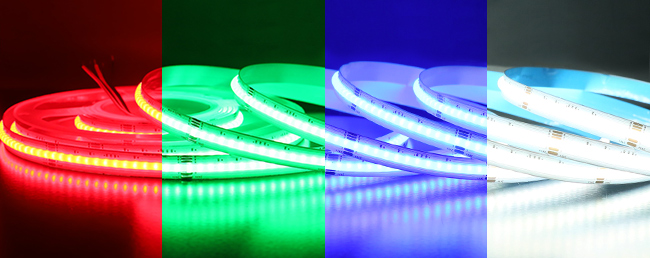

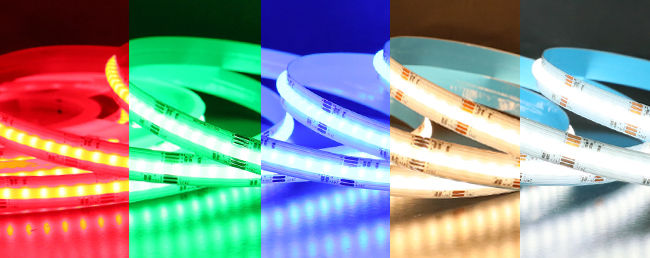

COB LED light strip can be made into any color (1800K 2200K 2700K warm white, 3000K 3500K soft white, 4000K natural white, 5000K 6000K daylight, 13000K cold white, red, green, blue, yellow, purple, pink, CCT adjustable color temperature, color changing RGB, RGBW, RGBCCT, and dream color addressable RGB / RGBIC, addressable RGBW / RGBWIC). Explore SuperLightingLED's COB LED strip lights and experience dotless lighting effects immediately.

Shop by Flexible Cob Led Strip Type

White COB LED Strip

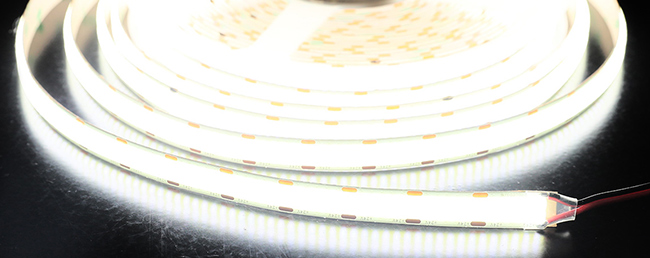

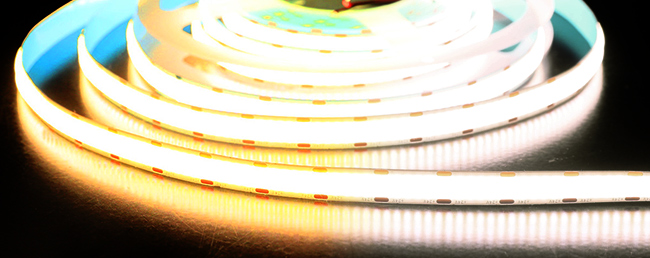

White COB LED strip specializes in simple and uniform pure white light illumination, makes sure places are well-lit, meeting the basic needs of daily lighting. Featuring a dense arrangement of LEDs, COB white LED lights minimize point light sources and ensure a smooth and continuous lighting line without light spots. High density also brings high brightness. These two key points make them suitable for lighting projects with high aesthetic requirements.

Thanks to its simple structure without complex circuitry, COB LED white light strip is more energy-efficient, longer-lasting and economical. White COB light strips are available in a wide range of color temperatures, including warm white cob led, natural white and daylight white. For indoor light decoration, COB LED under cabinet lights and kick-toe lighting are becoming more and more popular. All white COB LED strips are dimmable. You can use a dimmable power supply to power and dim single white COB LED tape light. Accessories for these white cob led strips please check here.

Non-white Single Color COB Strip

Non-white static color COB strip refers to COB strip light that can only emit one color and the color is not white, often used in special lighting designs.

There are multiple color options available. Yellow cob led lights are widely used in restaurants or cafes to create a warm atmosphere, especially in winter. COB led blue tape light can be used inside fish tanks or aquariums to add a fresh tone. Amber led cob and red cob led strip can be applied in warning signs, while green led cob strips are suitable for noting escape entrances and exits. These flexible strip tape lights can also be used together to create a happy atmosphere during holiday celebrations.

Apart from color, these chip on board led strip lights are basically same as COB white LED lights. They are spotless, flexible and cuttable, freely dimmable with a dimmer, and connected with cob light fittings.

Tunable White COB LED Strip

Tunable white COB LED strip tape light, also known as CCT COB LED strip, allows you to freely adjust color temperature ranging from 2700k warm white to 6500k daylight white. Warm white COB LED strip, featuring reddish hue, is usually associated with comfort and relaxation, widely used in bedrooms, hotels and other places to create a cozy feeling. COB LED daylight tends to have more bluish tone, related to the feeling of seriousness and formality, suitable for places such as offices and hospitals. These COB LED flexible strip lights are cuttable with scissors, and can be quickly linked together using cob led strip light connectors to achieve long distance illumination.

Linear COB dotless LED strip can be mounted within LED Aluminum Profile to better diffuse light. With one single COB CCT LED strip, needs of different scenarios can be easily satisfied. When you need to work, you can switch tunable COB LED to 6500k to help focus your attention. And If you want to kick back and enjoy a movie, just turn to COB LED warm white 3000k to create perfect cozy ambiance.

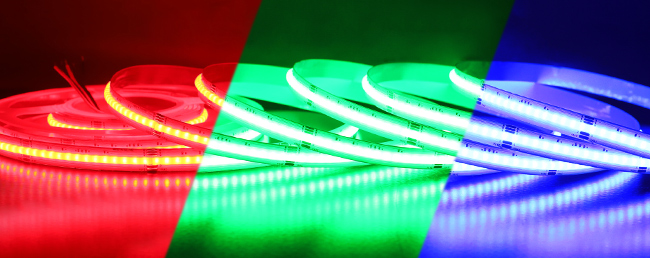

RGB COB LED Strip

As a professional rgb cob led strip manufacturer and online seller, Super Lighting LED is deeply engaged in the field of flexible cob chip on board technology, committed to providing customers around the world with continuous led linear lighting strips with high reliability and excellent luminous efficacy.

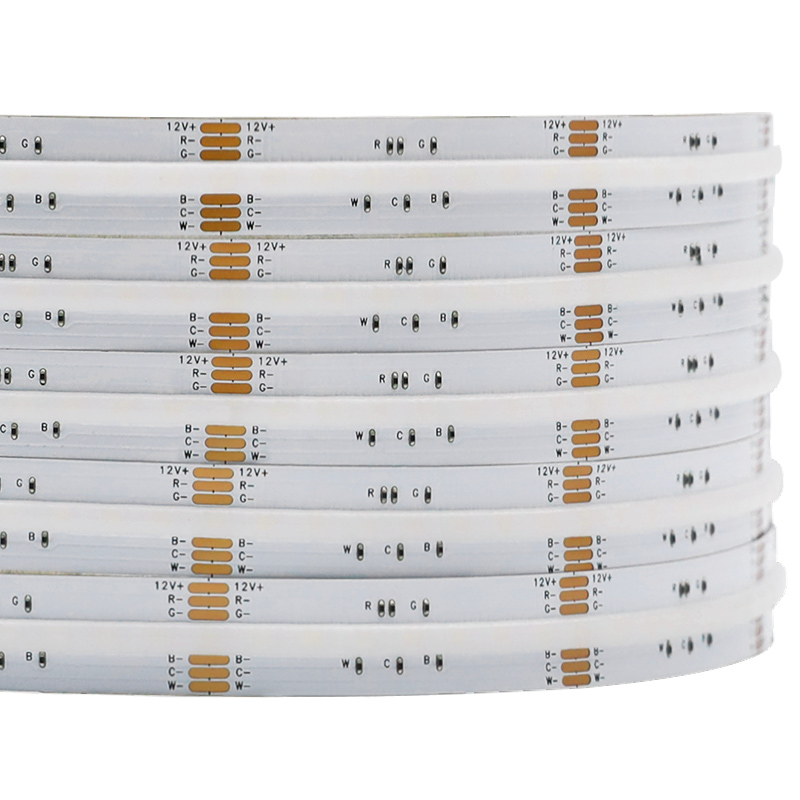

COB LED strip RGB can emit vibrant, colorful light, perfect for scenes that need to change colors. Utilizing chip on board technology, COB RGB LED strip features red, green and blue LEDs densely mounted on a flexible circuit board. Every three LEDs is a group, together providing a wide range of colors through different mixing ratios. It is necessary to have a controller in hand to freely adjust the colors of LED strip lights COB.

All LEDs are covered with a fluorescent coating. It not only helps RGB COB LED strip light to mix colors better, but also diffuse light, offering a uniform COB LED RGB illumination without spots or dark areas.

Stick RGB LED COB strip light behind your computer, bed or around the ceiling corner to set indirect lighting for your room. It provides soft, bright light that is gentle on the eyes, and helps create various mood themes. COB led connector parts are available for quick installation.

COB LED Strip RGB+W

RGBW COB LED strip, as the name suggests, refers to a COB LED light strip that not only has red, green and blue LEDs mounted on PCB, but also comes with additional white LEDs. This design allows rgb+w cob led strip to emit a more natural pure white light apart from colorful lights. Besides, white LEDs of COB RGBW LED strip can also add brightness to other colored lights, providing a more even and smooth glow. Our LED RGBW COB tape light is usually powered by 24V power supply, very safe to use.

In COB LED RGBW strip, white LEDs are available in color temperatures of 3000k, 4000k and 6500k. COB LED strip lights are recommended to be installed within silicone neon LED diffuser to protect against external damage and enhance aesthetics. LED strip COB RGBW is a perfect solution for shopping mall lighting, home lighting and stage party lighting due to their wide range of color display and excellent seamless illumination effect. Easy to use with compatible cob led strip connector accessories.

RGBW COB LED Strip Spectrum Test Report

(3000K),

(3000K),  (4000K),

(4000K),  (6000K)

(6000K)

RGBCCT COB LED Strip

RGBCCT COB LED flex strip is a multi-functional LED COB tape light. It can emit thousands of colorful lights and give off pure white light, also known as rgbcw 2700k-6500k strip light. The color temperature is adjustable from 2700k warm white to 6500k daylight white, which is suitable for different scenarios.

Due to complex functions, RGBWW COB LED strip has higher working power and requires a more powerful driver. Compared to traditional color changing SMD LED tape light, RGBCCT dotless COB LED strip ensures every LED is in direct contact with PCB, therefore has better heat dissipation performance. Its connector also varies from smd led connectors.

If you want to make the COB style LED strip light dissipate heat faster and last longer, you can put the FCOB RGBCCT light strip into an aluminum channel to better help conduct heat. This also helps to prevent other physical damage.

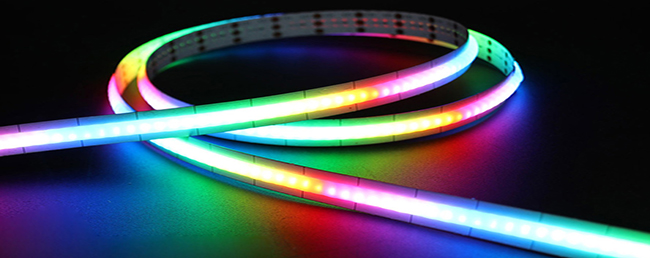

Addressable COB LED Strip

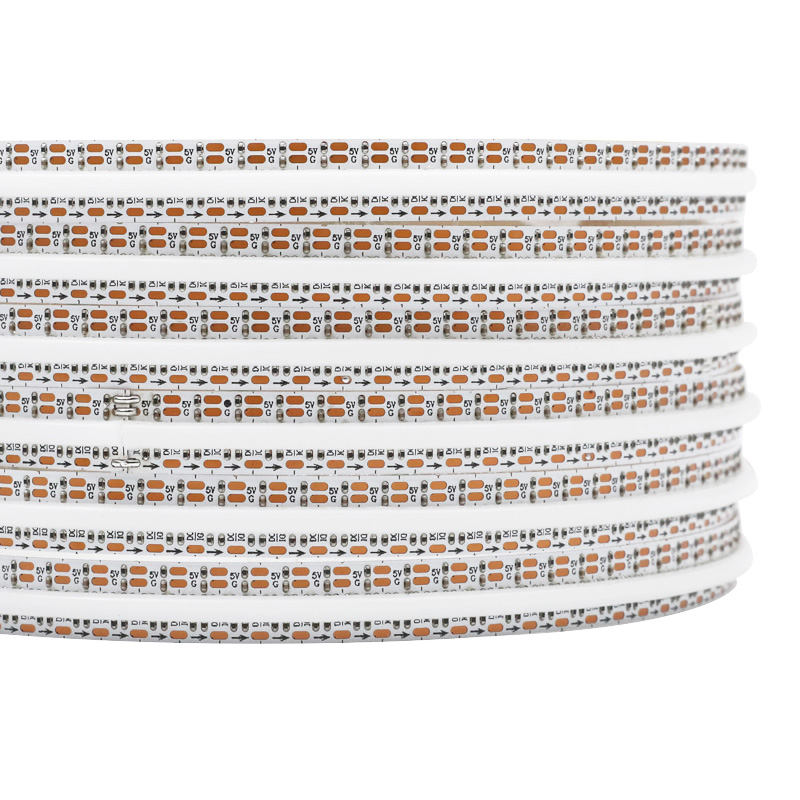

COB addressable LED strip refers to LED COB light strip installed with IC, aiming to achieve a variety of dynamic color change effects. Smart COB LED strip usually comes with WS2811 chip to manage the color and brightness emitted by each group of LEDs. Due to the high density of LED COB lighting and precise control of WS2811, COB LED strip addressable can display more detailed lighting effects such as chasing, twinkling and waving.

Pixel COB lights LED tapes are available in a variety of colors, including white, CCT, RGB and RGBCCT. RGBIC COB LED strip is favored by lots of stage lighting designers. With a programmable LED controller, DIY COB LED specific lighting details on your own is possible. The surface or back of the addressable COB LED strip usually has three soldering points. You can cut along the black marking lines and solder the COB strip through wires to establish a stable electrical connection or just use some solderless quick led cob strip connectors.

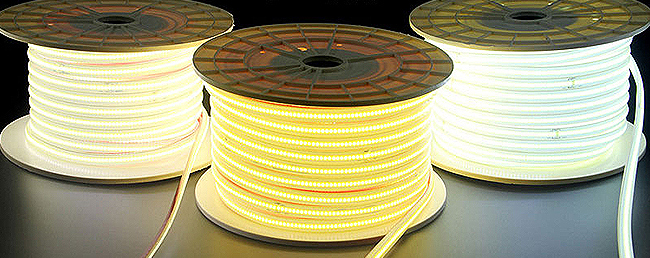

Waterproof COB LED Strip

Waterproof COB LED outdoor strip light is an excellent choice for exterior lighting projects.

There are three waterproof ratings, including cob led ip65, ip67 and ip68. IP65 COB LED strip is resistant to dripping and splashing water, but the PCB can't contact with water. IP67 COB LED strip is entirely waterproof and suitable for outdoor use, such as lighting your gardens. They can also be applied in bathrooms or kitchens where there is frequent water contact. IP68 COB LED strip are suitable for use in underwater environments, perfect for lighting the border of swimming pools and fountains.

Silicone COB LED strip, also called COB LED neon strip, is a special kind of COB LED waterproof tape light. It combines the advantages of both cob leds and neon rope lights, very flexible, not easy to break during bending, no light spot or dark area, with outstanding water-resistant ability.

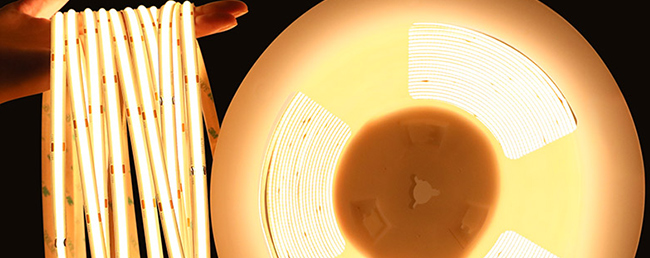

Super Bright COB LED Tape Light

Brightest LED COB tape strips have super high lumens, able to provide ample illumination for homes, offices and warehouses. These large COB LED strips are usually available in multiple rows, including double, triple, quad and five rows. High brightness and high power COB LED lights have an adhesive backing that can be peeled off for easier installation. These super bright LED COB light strips with widths of 20mm or 30mm can be fit into extra wide aluminum channel to illuminate a large area.

Long COB LED Light Strip

Long linear COB LED light is suitable for long-distance lighting projects, available in COB LED strip 10m to 30m. Just one strip LED COB can realize long stretch of smooth and continuous illumination without voltage drop, bringing refreshing visual experience. No worry about cutting and connecting multiple cob led tube lights or using multiple power supplies, making it easy to set up and saving installation time.

Ultra Slim COB LED Tape Light

Mini COB LED light strip features a compact design and can be easily inserted into slits and grooves. 2mm, 3mm, 4mm and 5mm COB LED strip are available. Despite their small size, these slim COB LED strips have great performance, providing bright and dotless light. Multiple color options are available and there is even a waterproof version of thin COB LED strip. These narrow LED COB lights come with an adhesive backing, making them easy to fit into silicone neon diffuser for accent lighting.

SlimLine COB LED Strip Collection – Revolutionizing Ambient Lighting

5V COB LED Strip

5V USB COB LED strip can be powered using the USB port with low voltage and high security. There are multiple colors options for you to choose from, including white and color changing. 5V COB LED strip light is powered by a 5V power supply, which reduces energy consumption and has a longer service life. These flexible light strips can be formed into different shapes. COB LED strip 5V is often used as car interior decorative lights to provide dazzling color effects.

120V LED COB Strip

110V COB LED flexible strip lights have stable lighting effect, suitable for professional industrial lighting projects. High voltage 120V LED COB tape is able to give off intensive light without dots. Unlike low voltage LED COB tapes which have voltage drop problem, these high power COB LED lights can realize long distance lighting, with consistent color from end to end. These chip on board LED strips require professional COB LED installation and maintenance to ensure optimal performance.

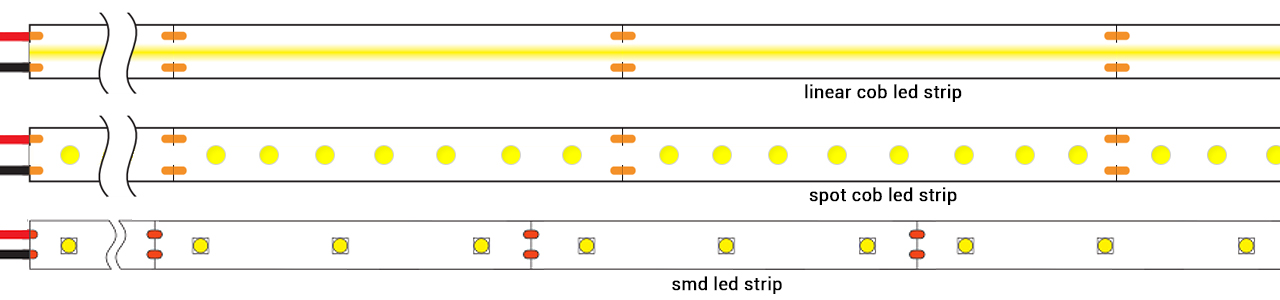

COB LED Strips vs. SMD LED Strips Technical Comparison

For users unfamiliar with COB (Chip-on-Board) light strips, they may appear similar to traditional SMD (Surface-Mounted Device) light strips. However, COB technology offers significant improvements in optical performance, durability, and energy efficiency.

The following comparison will help you better understand the unique advantages of COB light strips and why they are gradually replacing traditional SMD light strips in high-end lighting applications.

| Features | COB LED Strip | SMD LED Strip |

| Lighting Angle | 180° (no blind spots), 120° focued beam | 120° or with lens |

| Flexibility | Can be bent and wrapped 360° | Only supports flat bending |

| Color Rendering Index (CRI) | ≥90, ≥95 (max 98) | Typically 80-90 (95+ full-spectrum requires customization) |

| Thermal Management | Perfect (on-board chips) | Local hotspots |

| Light Spot Effect | Seamless linear light | Visible light points |

| Luminous efficacy | High | Medium |

| LED density | Up to 1408 LEDs/m | Typically 30, 60, 96, 120, 240 LEDs/m |

| Power consumption | 7.2W/m (at high density) | 14.4W/m (at the same brightness) |

SuperLightingLED FCOB Product Download

FAQ

1. What voltage is normally used to power a COB lighting strip?

Generally speaking, LED COB strip 12V and 24V COB LED strip light are more common. There are also cobb lights powered by special voltages, such as 5V low voltage, high voltage 110V-120V or 220V.

2.What is the biggest advantage of COB LED lighting strips?

COB strip lights are winning the market with their dotless and smooth line of illumination, with a layer covering high-density LEDs to distribute more even light.

SlimLine COB LED Strip Collection – Revolutionizing Ambient Lighting

3. Is COB strip LED flexible?

Yes, COB light LED ribbon strip is flexible and bendable. It can even be twisted if you like. But remember not to fold these tapes into sharp angles.

4. Is COB LED strip dimmable?

It depends. Not all chip on board lighting strips are dimmable. But for all LED COB lights now sold at SuperlightingLED, brightness can be freely adjusted with compatible controllers.

5. What is dim to warm COB LED strip?

Dim to warm COB in LED refers to a flex LED strip, tunable from 1800k to 3000k, changes not only the brightness but also the color temperature of the light during the dimming process. When you dim the lights, the color temperature will also be adjusted to a smaller value. (warmer in tone)

6.Can LED COB light strips be cut to custom length?

Yes, COB tape light can be easily cut to the length you want with a scissor. They can also be connected to each other via cob led connectors to light up long distances.

7.How to cut COB LED strip?

There are black lines marked on the COB lights LED to guide your cut. Just use a scissor to simply cut along these black lines. Do not cut other areas, as this will damage the strips.

8.How to connect COB LED strip?

There are two ways to connect these cobled strips: using a cob connector or soldering wires. The former is safer and simpler, while the latter is more stable.

9.How to install COB LED strip lights?

LED COB strip usually comes with an adhesive backing. Simply peel off the backing and stick cobb light strip to anywhere you like. You can also stick it into an aluminum profile or a neon tube for enhanced protection.

10.What are the application scenarios for these COB LED light strips?

You can see cobb lighting almost anywhere. LED COB LED tape lights can be used in both commercial and residential spaces. Recently, they are often selected as led cove lighting strips to light up ceiling or floor indirectly.

(0)

(0)

(1)

(1)