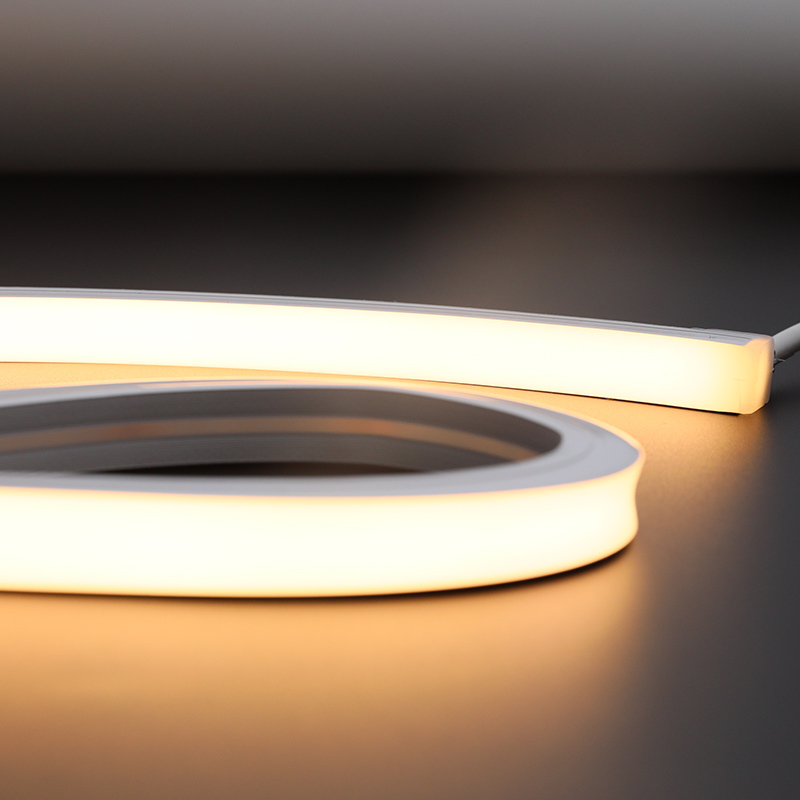

In order to apply to professional and commercial LED neon lighting projects that have very strict requirements on the appearance, we have introduced these aesthetic injection molded led neon rope lights. Since the LED strip and silicone tube are molded in one piece, the overall performance of the neon light will be more stable and able to break the conventional top and side light-emitting methods. In general, LED light strip is placed parallel or perpendicular to the neon light-emitting surface. This one-piece molding neon rope allows the strip to be placed diagonally (known as 3D), which distributes the stress on the PCB board during bending, thus reducing the risk of damage. What's more, these one-piece neon lights come with cut marks on the tubing so you can easily cut it to the length you want.

What is injection molding led neon rope light?

The biggest highlight of injection molding led neon rope lights lies in the seamless integration of the neon end caps and neon led tube through the hot pressing process. We heat the silicone material to a molten state to form liquid silicone and then use it to tightly envelope the end of the neon tubing. After cooling, neon led rope light with smooth and cohesive appearance can be obtained. So these led injection molding neon rope lights have an aesthetic look in details than handmade neon rope lights.

Injection molding neon lights vs Traditional neon lights

First, a continual and unbroken line of illumination, even at connection points, can be easily achieved, perfect for decorative lighting projects. Second, end caps are securely sealed, making these neon flex led strip lights IP67/IP68 waterproof, durable enough to withstand harsh outdoor environments. Lastly, these neon lights have a superior bending capability as the LED strip inside neon tubing is encased and stabilized in solid silicone and there is an impact-resistant plastic sheet placed under LED strip PCB to prevent strip breakage.

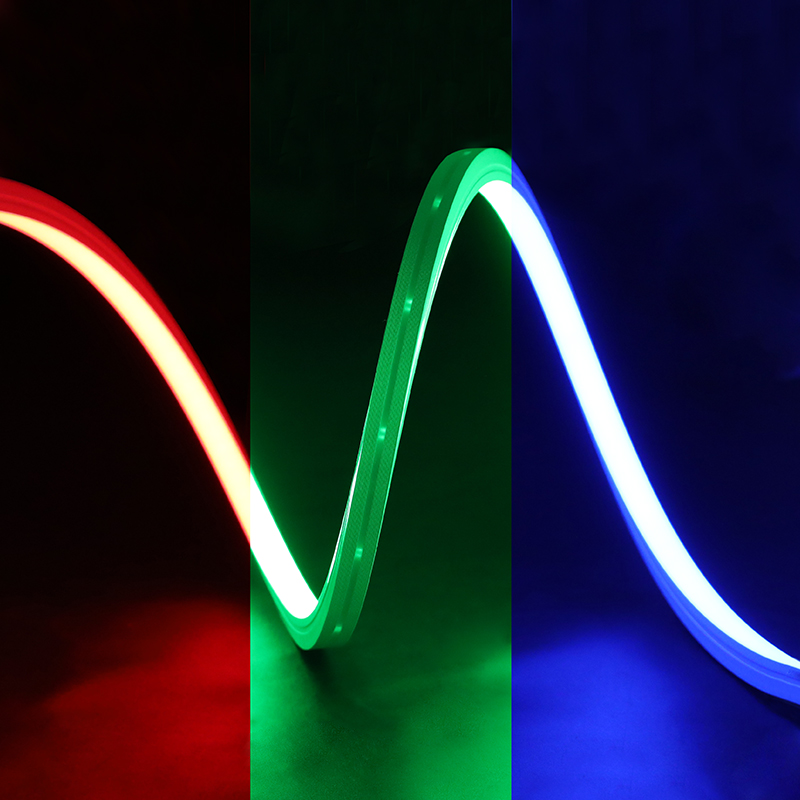

Our LED light strip injection molding neon lights can be customized in length, color, size, light emitting method, outlet type and length, please contact us if you have a need.

(0)

(0)